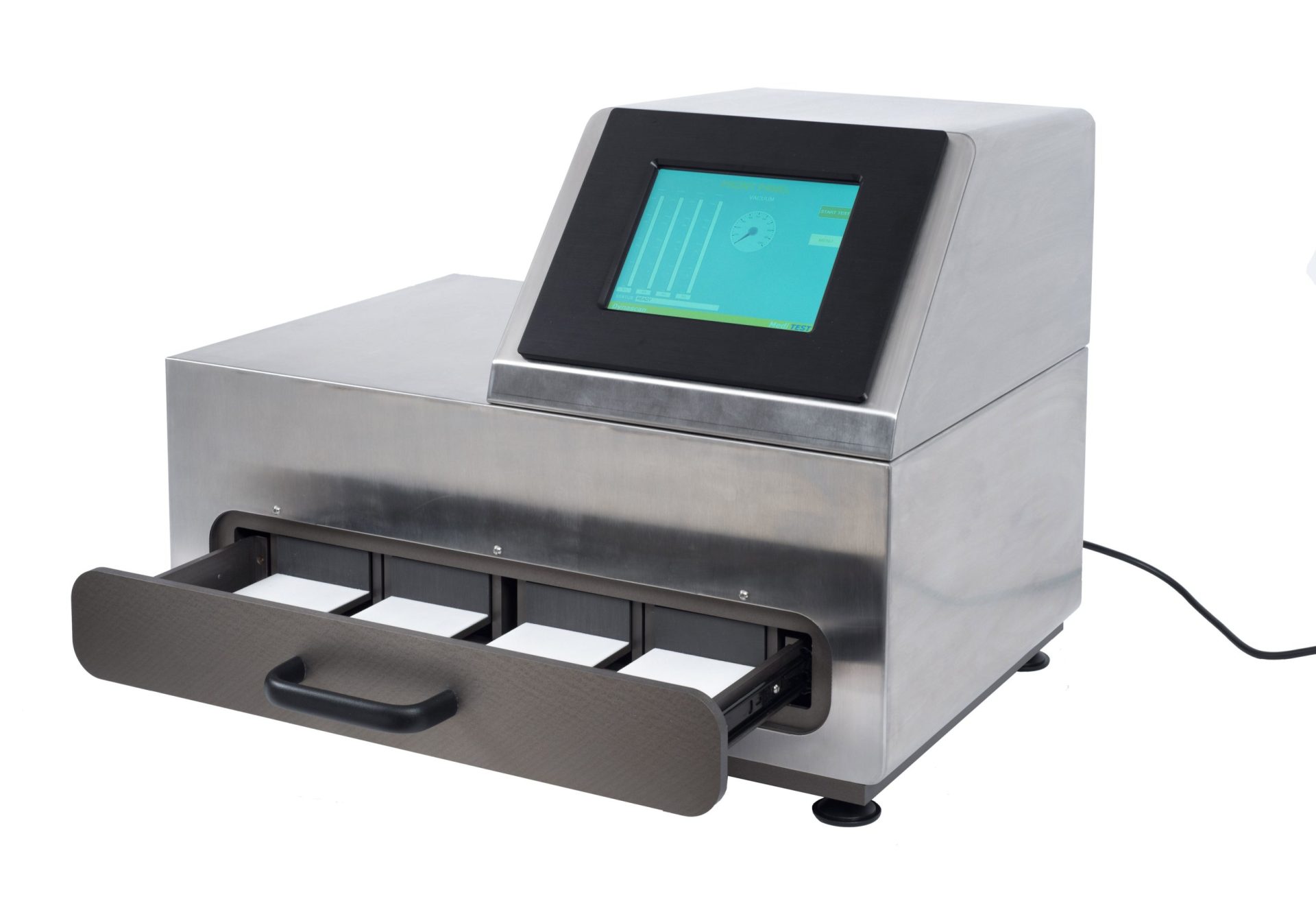

Dynascan MediTEST

Features

- No specialist tooling required

- Can detect leak holes down to 10µm

- 2, 4 or 10 standard pack testers with other sizes available

- Stainless steel case work and CGMP compliance

- Advanced software for easy perimeter setup

- USB and RS232 for easy data retrieval or storage

- Short test cycle time

View HOW the test is performed by clicking HERE.

Information

Weak seals or leakages are easily identified with the MediTEST range, efficiently highlighting any issues with quality assurance. Only a few seconds are required to detect holes down to ten microns, while the non-destructive nature of the test allows for flawless packaging to be reintroduced to the production line, significantly reducing waste and cost.

The MediTEST provides easy to read results, indications and graphical test data to aid analysis. Users can store test and meta-data in compliance with 21CFR Pt 11 and output these to a printer.

Modular and flexible design allows the packaging leak detection system to be optimised for each product application maximising sensitivity and minimising test time. A self-adjusting sensor system virtually eliminates the requirement for specialist tooling, with a front-loading tray enhancing ease of use.

Standard MediTEST systems can test either two, four or ten pouches simultaneously, with custom configurations available to meet the user requirements.

Specifications

Vacuum force leak detection system with computer control and touchscreen HMI

Custom configurations available

Better than 10 microns hole diameter

(Performance is a function of pack size, vacuum level and head space)

Down to 10 seconds

(Performance is a function of pack size, vacuum level and head space)

Two, four or ten packs simultaneously

Custom configurations available

2 channel – 140 (L) x 180(D) x 35(D)

4 channel – 140(L) x 90(W) x 35(D)

8.4” to 17” colour display with touchscreen

110/230V, 50-60Hz

USB and RS232

6 bar (200l/min)

Bench mounted or workstation, dependant on configuration

Grade 304 stainless steel casework

Can operate in compliance in 21CFR pt 11

CE marked